Aluminum injection casting is a cost-effective, high-precision, and versatile casting technique. In this technique, aluminum alloy is injected into hot casting molds. Some of the advantages include:

Read moreHigh-pressure aluminum die casting can be used for a variety of designs and sizes of parts. It is particularly ideal for high-precision, complex-shaped, and parts that carry significant loads. Some pa

Read moreMetal injection mold manufacturing involves several stages. Generally, the following steps are followed: Design: The design of the injection mold is done based on the shape, size, and features of t

Read moreMolding, casting and machining in the same place in aluminum casting, increases efficiency and reduces costs in the production process. The benefits of molding, casting, and machining in the same plac

Read moreHigh-pressure aluminum injection molding can be used to produce a wide range of parts in the automotive industry. Some parts that can be cast using high-pressure aluminum injection molding include:

Read moreHigh-pressure aluminum injection molding can be used to produce a wide range of parts in the lightning industry. Some parts that can be cast using high-pressure aluminum injection molding include:

Read moreHigh-pressure aluminum injection molding can be used to produce a wide range of parts in the machinery industry. Some parts that can be cast using high-pressure aluminum injection molding include:

Read moreHigh-pressure aluminum injection molding can be used to produce a wide range of parts in the reducer industry. Some parts that can be cast using high-pressure aluminum injection molding include: Re

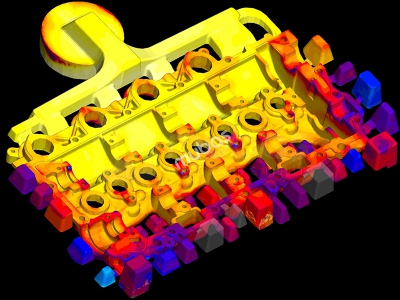

Read moreAluminum injection casting research and development (R&D) and design involves a variety of stages, including: Concept development: The initial stage of R&D and design involves the developme

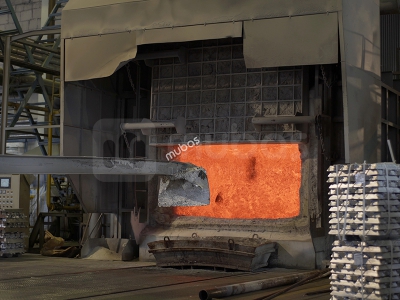

Read moreAn aluminum injection casting melting facility is a facility used to melt and process aluminum alloy for use in the injection casting process. The facility typically includes the following main compon

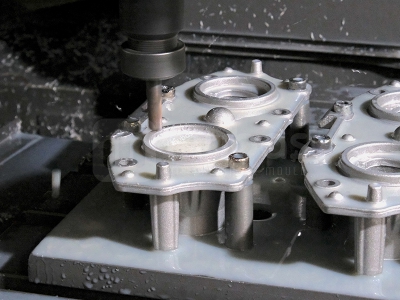

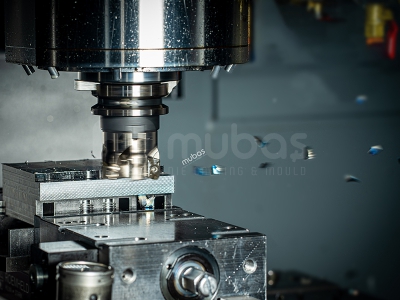

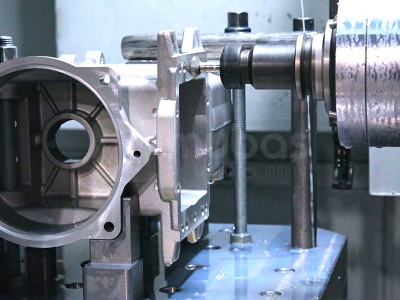

Read moreCNC (computer numerical control) machining is a process used to produce precise and accurate parts from aluminum castings. The process involves using a CNC machine, which is a computer-controlled mach

Read moreSurface treatment is a process used to improve the appearance, durability, and performance of aluminum injection parts. Some of the most common surface treatments for aluminum injection parts include:

Read moreHistory of Diecasting Die casting was developed by Sturges in 1849, Barr in 1852, Pelize in 1856, Dusenbury in 1877, etc. people have patented manual machines. This is what Ottmar Mergenthaler call

Read moreMetal injection is the process of press casting in the old say. It is the process of injecting the metals heated up to melting temperature into pre-prepared molds by applying pressure with special mac

Read moreMold production is the most important factor in the aluminum injection industry. Our company started out in 2000 with customer-specific mold production and produced many kinds of molds. Since 2009 we

Read more