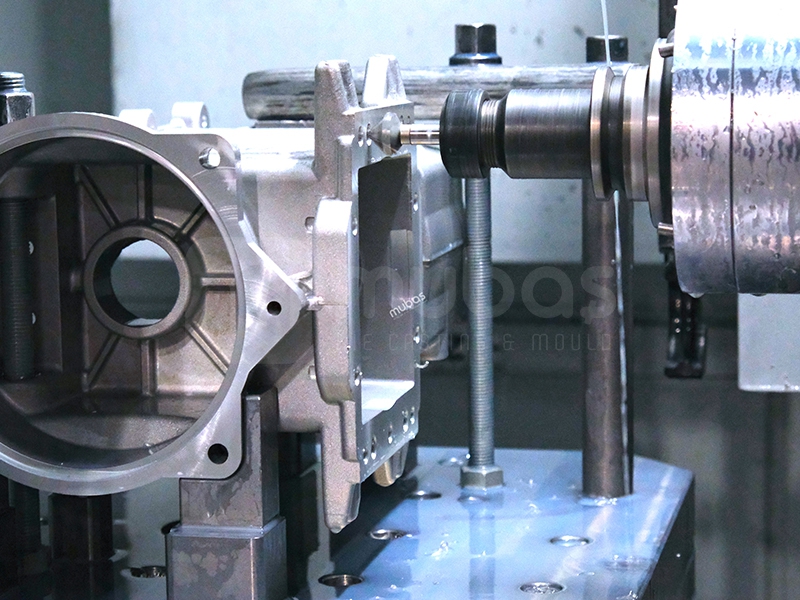

Aluminum Casting Parts CNC Machining

CNC (computer numerical control) machining is a process used to produce precise and accurate parts from aluminum castings. The process involves using a CNC machine, which is a computer-controlled machine tool, to remove material from the aluminum casting to achieve the desired shape and tolerance.

The process begins with the aluminum casting being placed on the machine and secured in place. The CNC machine then uses cutting tools, such as end mills and drills, to remove material from the casting according to the programmed instructions. The cutting tools are typically made of high-speed steel, carbide or diamond.

CNC machining can be used to produce a wide range of aluminum casting parts, including:

Complex geometries: CNC machining can be used to produce parts with complex geometries and intricate details.

High precision: CNC machining can produce parts with high precision and tight tolerances.

Surface finish: CNC machining can produce parts with a high-quality surface finish, such as a mirror finish.

Versatility: CNC machining can be used to produce a wide range of parts for different industries.

Efficiency: CNC machining is a highly efficient process that can produce large numbers of parts quickly and accurately.

Quality control: CNC machining allows for quality control measurements, such as dimensional control and surface finish control.

The CNC machining process is a cost-effective and efficient method for producing high-precision aluminum casting parts. It is widely used in many industries, including aerospace, automotive, medical, and industrial machinery.