Casting&Foundry

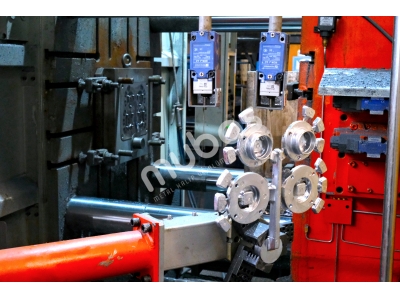

With 6 automated high-pressure aluminum casting machines with 400T - 1350T clamping capacity and an average age of 4, our company can quickly and perfectly produce parts from 50 grams to 10 kilograms for its customers.

Our large machine park has been built with full automation for each process and control section in order to provide 24 hours uninterrupted production in 3 shifts. Mubaş Metal has transformed the knowledge and experience gained over the years into a proactive business approach.,

Foundry Machinery Park

-

400 Tons Aluminum Die Casting Press (2pcs.)

-

580 Tons Aluminum Die Casting Press (1pcs.)

-

650 Tons Aluminum Die Casting Press (1pcs.)

-

750 Tons Aluminum Die Casting Press (1pcs.)

-

1350 Tons Aluminum Die Casting Press (1pcs.)

Auxiliary Equipment

-

Cell-type lineer spraying

-

Porous Plug Dosing Furnaces

-

Part Picking Robots

-

Orbital Grab Robot

-

Aluminum Casting Robot

Our company, which is engaged in high pressure aluminum injection die casting and cnc processing, always continues its production with affordable cost and high quality. We are at your service for metal injection die casting and machining demands of our customers in the automotive, lighting, machinery and reducer sectors by producing at world standards with the goal of 100% customer satisfaction. You can contact our company to get information about aluminum injection casting mold manufacturing, casting and cnc machining processing prices.

Mubaş Metal Mold Injection; manufactures aluminum injection die casting, high pressure aluminum metal injection die casting, metal injection die casting, aluminum die casting, metal die casting.